Building and Facility System

KPT is one of the Leading Main Contractor for Semiconductor

Design

Design

Authority submission - FSSD, JTC, URA, BCA

Authority submission - FSSD, JTC, URA, BCA

Building works include layout changes, wall & door works, painting works...etc

Building works include layout changes, wall & door works, painting works...etc

Fire fighting include sprinkler, fire alarm, de-smoke ...system.

Fire fighting include sprinkler, fire alarm, de-smoke ...system.

Exhaust (HVAC works including Piping, Ducting, AHU, FCU)

Exhaust (HVAC works including Piping, Ducting, AHU, FCU)

Chilled water system

Chilled water system

Gas system

Gas system

Central VOC abatement system

Central VOC abatement system

● ISO 6 (Class 1K) for test machine

● Cleanroom Area: 200m2

● FFU w Dry Coil Circulation

● Partition, Ceiling Grid Installation

● Mini-Environment for tools

● ISO 5 / 6 (Class 100 / 1K) for Implanter

● Cleanroom Area: 180m2

● FFU w Dry Coil Circulation

● Raised Floor, Partition, Ceiling Grid Installation

● Room Pressure to control cross contamination

● ISO 3 / 6 (Class 1 / Class 1K) for Sputter Machine

● Cleanroom Area: 800m2

● FFU w Dry Coil Circulation

● Raised Floor, Partition, Ceiling Grid Installation

● Convert Existing underground Car Park to warehouse storage

● Warehouse Area: 1200m2

● Fire safety system include MA, De-Smoke, Sprinkler, HR, fire compartment… to meet local code requirement

● New passenger lift works

● New wall, hacking, piling, …CSA works

● HVAC requirement for office, controlled TT/RH for warehouse

● Card Access, CCTV, Fencing, Decom, for warehouse security management

● New build include base, wall, roof… for new Cold room

● Warehouse Area: 80m2

● Low Temperature control 10 deg C

● Chemical storage control to meet local code requirement

● CardAccess, CCTV…etc security management

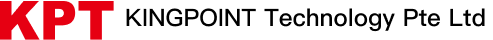

● To erect new structure out of existing building

● For new cleanroom MA / Exhaust riser

● Height : 28m

● Design, Calculation, & BCA submission

● Façade works

● Ducting insulation

● Maintenance platform and access

VOC Abatement System Project

● Design and Install new VOC abatement System for GF Solvent Exhaust

● System Capacity: 60,000CMH x 2 sets

● VOC Abatement Equipment include: Rotor, Oxidizer, 2nd Fan & Desorb Fan

● Mechanical works include: SS304 Exh Duct, SOX Fan, ROR, N

● Utilities supply works include: ROR, Drainage, Natural Gas, N2, CDA, Power…etc

● Electrical works include: VSD, wiring and power

● I&C works include: temperature, pressure, system operating status monitoring and control

● Others include plinth works, wall and slab penetration, maintenance platform…etc

● Whole abatement system submit to NEA and get approval

● On-line GC FID for leaving air monitoring

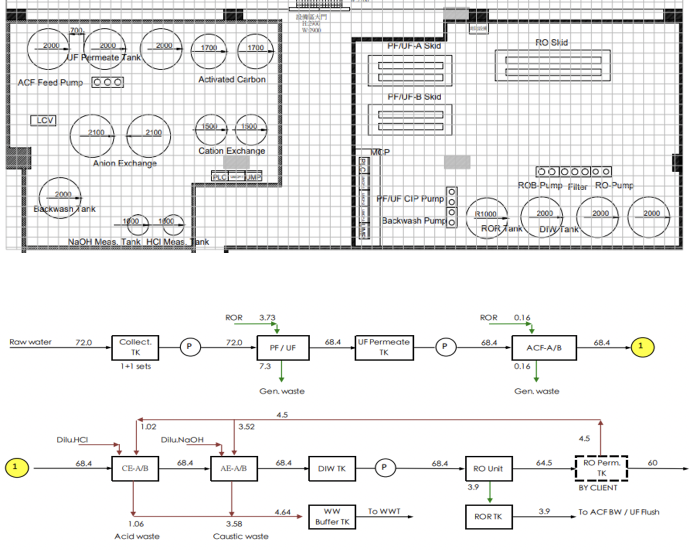

PCW System Expansion

● Design and Install new PCW for EPI tools

● PCW Capacity: 100CMH@90m (N+1)

● Mechanical works include New Pump, Cartridge Filter, HEX, Tank, CHW piping & PCW SS piping

● Electrical works include: VSD, Bornitron, wiring and power

● I&C works include temperature, conductivity, pressure… monitoring and control

● Others include plinth works, wall and slab penetration, fire-strop…etc

● Chemical Treatment

Cleanroom Conversion

● Design and build a Bay / Chase (ISO 3 / 5) Cleanroom

● Production Area (ISO 3): 200m2

● Maintenance Area (ISO 5): 400m2

● EC Fan motor FFU for cleanliness control

● Dry Coiling Coils for TT 23 +/- 1 deg C; RH 45 +/- 5% control

● Ni-Co Raised floor cover production area

● LED fluorescent light

● Pre-Action type sprinkler system

● PLC Realtime TT/RH/Pressure Control and Monitoring

TD Lab

● EMI LAB Area: 140m2

● Facilities penetration: Power & Lighting, HVAC Ducting Works, Sprinkler Heads

● Individual transformer for room power supply

● Machine Hook up: Power Wiring, PCW, CDA, N2

● Room Temperature control 23 +/- 2 deg C (2+1 FCUs)

● Make up Air for Humidity Control RH 45 +/- 10%

● FSSD Submission and get approval

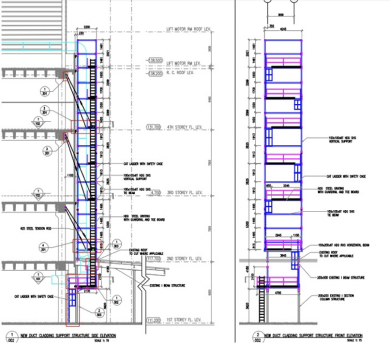

LHF Reclaim System

● Capacity: 72 m³/h LHF raw water recycle 60m³/h DI system

● Existing plant dismantle

● Civil foundation and operating platform

● Production cleanroom tools drain line diversion to new system

● FAC Installation for reclaim system

High purity piping

● N2 Ar H2 O2 He gas piping work from Gas yard to main Fab

● Provide orbital welding for 8-inch-high purity piping installation

● Qualification for Gas line purity

CDA system

● Design and build CDA supply system

● Capacity: Flow rate 67m³/min, pressure 8.5kg/cm³

● System Equipment supply: compressor 3 set 4020CMH/each dryer, heater, exchanger, receiver tank, etc.

● Utilities include: 6.6kV, 415V electrical, Gas, CW, PCW, system control and monitoring , etc.