Fabrication

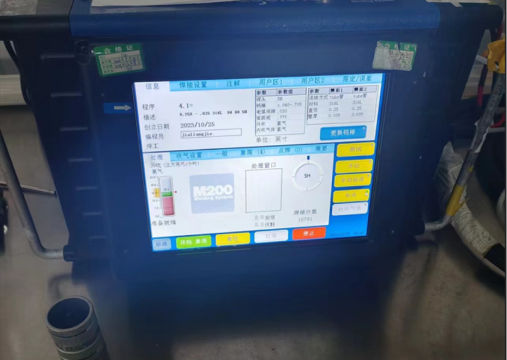

● Specialized submain CNC online production, higher product quality, better stability. (such as accuracy, tolerance, welding)

● Automatic online numerical control ID welding.

● Fabricated by design drawing and SOP.

● Shipping documentation delivery, including material COA、assembly serial number, assembly index (layout plan)、test report and warranty.

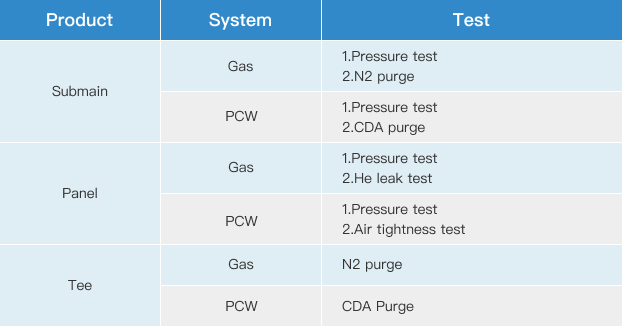

Test

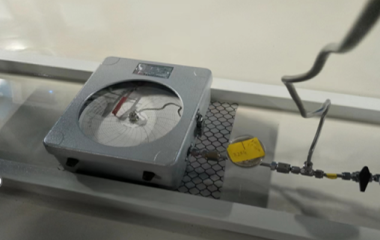

Clean room assembly

Clean room assembly Pressure test

Pressure test He leak test

He leak test

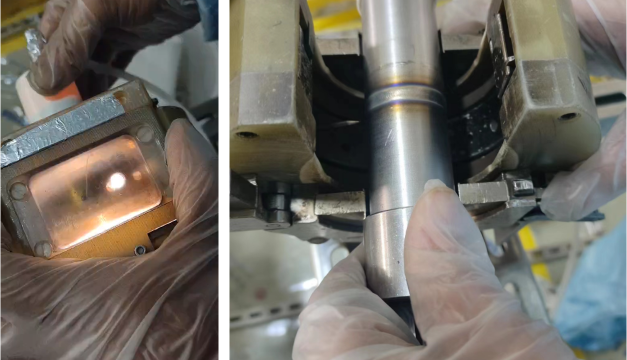

● We execute the inspection of material component during fabrication to prevent from welding leakage.

● Final acceptance test for submain and panel are required as our standard procedure, description as following:

Packing

● The protective cap use plastic to encase in the end of submain.

● All valves are encased with bubble wrap and carton for avoid being crashed.

● Submain are encased with bubble wrap then fix inside the wooden case.